Vernier Caliper Parts and Their Main Function

Definition:

A vernier caliper is a precise measuring tool which is used to measure linear dimensions accurately.

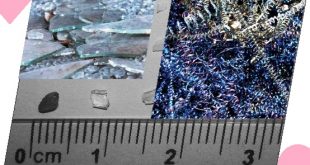

Vernier caliper is a usually used for lateral measurements like lengths,widths,diameters and depths of different engineering objects and parts to accuracy of ±0.1 mm or one thousand of an inch(0.001″) depending upon which scale based(metric/imperial) and what resolution(0.01~0.05 mm) of Vernier caliper you are using.

Vernier caliper was invented by a French mathematician Pierre Vernier in 1631 and thus the name vernier caliper.

It is used for measuring lengths and diameter of round parts and objects like cylinders, washers and o,rings and very useful tool for this purpose because of its measuring jaws holding capability for round shape objects. It’s modified form of steel rule and measures the lateral and longitudinal dimensions to precision.

Vernier caliper is most commonly used tool in machine shop,welding, fabrication and foundry workshops and many other fields of engineering and technology, for both small and large objects because of its vast range in terms of size is available in the market and it is very economical compare to micrometer .

Vernier caliper parts and construction:

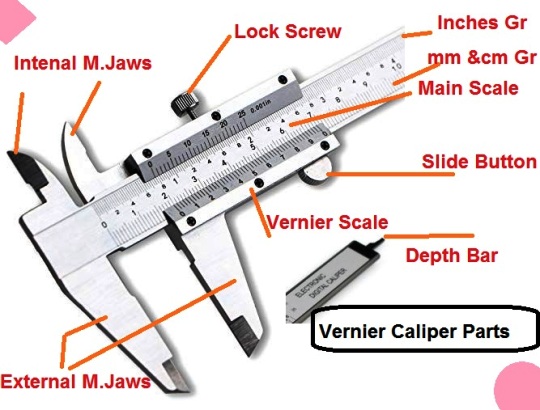

Vernier caliper consist of following parts also identified in image below:

Main scale:

It is comprises of a long rectangular metal strip which has two fixed jaws on one end for each internal and external measurements on the upper and lower side respectively.

The scale is graduated on this scale in inches on upper side and centimetres and millimetres on its lower side as shown in picture.

It’s a small rectangular strip compare to main scale and graduated with a special relation to the main scale and can slide over the main sale of vernier caliper.

It has two measuring jaws on one end for each internal and external measurements on the upper and lower side respectively.

Vernier scale jaws are same like main scale jaws except that its jaws are movable when it slides over main scale to open or close position according to size of job to be measured.

Measuring jaws:

The jaws of each main and vernier scale together makes the measuring jaws of vernier caliper those are used to hold the object firmly.

Initially there were lower measuring jaws only, but after that extended to upper side for both scales, that makes vernier caliper capable of measuring inside dimensions too.

Upper or internal jaws:

Internal or upper jaws are designed to measure internal dimensions like internal diameter of hollow cylinders, washers-rings, o-rings and tubes.

External Jaws:

These jaws are generally used to measure external dimensions for example length width and breadth of small objects.

Depth Bar:

It is used for depth measuring and is provided in a slot back side of main scales in which it slides out as jaws opens because its one end is linked with vernier scale.

Lock Screw:

Lock screw installed on vernier scale which is to stop the relative motion of vernier scale and helps to freeze a certain measuring point. It’s helpful to avoid measuring errors. Its means first we open the jaws to place the measuring object to and then close to hold the object and lock the vernier scale so the measurement values will not change during reading process of vernier caliper.

Slide button:

Its also called thumb rest a little metallic button which is rigid part of vernier scale has knurling on its handling side and used to open the jaws by sliding vernier scale over main scale.

Dial lock screw:

It’s provided in dial calipers to correct zero error.Installed on Dial of vernier caliper its unscrewing allows dial to rotate and after setting up of zero error its screwing freezes the dial rotation.